solutions, not pollution.

Carbon Fertilizer Manufacturing is an environmentally beneficial solution to an age-old waste problem; biosolids. We responsibly turn the biosolids waste disposal problem into a sustainable soil restoration solution that benefits the soil, human health, the environment, and climate change.

- Our process uniquely remediates biosolids and provides an endpoint for PFAS and volatile organic compounds (VOCs) that cause odors.

- Our low emission process meets the strictest air quality standards nationally and improves environmental justice associated with biosolids management.

- Our product restores soil health by improving hydration, nutrient management, and pH buffering in perpetuity while fertilizing plants with “slow release” nutrients and feeding the soil with organic matter.

- Our product replaces “fast release” chemical fertilizers that degrade soil and absorb excess nitrogen and phosphorus that pollute waterways.

- We provide a climate change tool with a carbon-negative lifecycle Greenhouse Gas (GHG) footprint based on avoided disposal emissions, avoided chemical fertilizer manufacturing and use, and carbon sequestered in soil.

There is no such thing as organic waste, only wasted organics.

City of Christchurch, New Zealand Solid Waste Plan (2006)

waste not.

Biosolids are the separated solids from municipal wastewater treatment facilities that are constrained in reuse by their contaminants, and typically disposed of by municipalities in landfills and incinerators or beneficially utilized in land application and composting. Biosolids typically contain traces of PFAS compounds, microplastics, pharmaceuticals, and other volatile organic compounds (VOCs) that constrain their beneficial reuse, and cause odors and environmental injustice in surrounding communities. Thermal treatment technologies (i.e., gasification, incineration, and pyrolysis) are the only known methods for reducing PFAS compounds and eliminating odors. However, not all thermal treatment technologies are equal. Our pyrolysis process is designed to maximize solids recovery, minimize air and GHG emissions, and remediate PFAS and other VOCs. We meet industry challenges head-on by offering wastewater utilities a solution that remediates biosolids and generates a desirable beneficial use product it while benefiting the climate and avoiding environmental injustices with ultra-low air and odor emissions.

Why waste it when we can now recycle it?

Northeastern Biochar Solutions' technology provides the first commercial scale solution that decontaminates biosolids and recycles it into a valuable carbon fertilizer product that addresses soil degradation issues.

- Our process remediates and recovers solids, instead of burning them, to eliminate PFAS and VOC contaminants and radically reduce regulated air and greenhouse gas (GHG) emissions.

- Our product, Carbon Fertilizer, is composed of avoided emissions relative to incineration, and contains nature’s recipe for sustainable soil (i.e., organic matter, carbon, and nutrients).

- Our facilities replace incinerators which are currently being phased out and not replaced due to high regulated air and GHG emissions.

from nuisance to nourishment.

Cities today are nutrient deserts. Reliance on chemical fertilizers and sprays has devastated soil biology, reducing the diversity and amount of nutrients in our food supplies. We are tapping one of the largest nuisance-wastes nationally, a bio-nutrient resource generated by society, to produce a new type of bio-fertilizer that restores soil and the nourishment it once provided.

Carbon Fertilizer restores the carbon-nutrient cycle that fed humanity for over 10,000 years. It recycles nature’s recipe, our manure, back into the soil after removing PFAS and other contaminants introduced by the modern world. Its carbonized form benefits soil biology and hydration perpetually.

- Pyrolysis fixes, petrifies, carbon in a form that will reside in soil for centuries, benefiting hydration, plant roots, fungi, nutrient management, and microbial communities perpetually.

- The organic matter entrained in the carbon feeds microbes, stimulates biodiversity, proliferates life, and helps generate nutrient-rich foods nourishing human health.

- Nutrients are released “on demand” to nourish plants and ensure they do not contribute to nutrient pollution like “quick release” chemical fertilizers.

more than just fertilizer.

Carbon Fertilizer is not your average fertilizer. In fact, it's so much more.

Carbon Fertilizer is not your average fertilizer. Carbon is a far better binder than the salt compounds found in chemical and mined mineral fertilizers. Salt is corrosive and dissolves in water which yields a quick nutrient release that causes nutrient losses/pollution and erodes soil organic matter and carbon in the process. Our product uses Carbon to bind organic matter and nutrients in a way that restores soil while making nutrients available to plants. Replacing chemical fertilizers with Carbon Fertilizer increases soil organic matter and soil carbon while reducing salt application and its corrosive impact on soils. This simple act helps to quickly restore soil life as it improves soil hydration and nutrient retention and lowers salinity.

Carbon Fertilizer is so much more than fertilizer. Its particle size and composition are perfect for binding rock dust, mineral clays, and other dry mineral enhancements including conventional fertilizers while its adsorbent properties facilitate the addition of liquid nutrients to the carbon. Its compatibility with agricultural and residential dry fertilizer spreaders provides a simple application method that many bio-fertilizer products struggle with. Furthermore, when Carbon Fertilizer is blended with chemical and mineral fertilizers, it helps to absorb nutrients and make them accessible to plants as needed to reduce nutrient application over time.

thermal cleansing.

We transform biosolids from nuisance to nourishment utilizing a combination of pyrolysis, advanced thermal oxidation, drying, and benchmark air treatment housed in a specialized building.

Our process separates PFAS and other volatile organic compounds (VOCs), and energy compounds from biosolids utilizing high-temperature pyrolysis. The contaminants and energy compounds are combusted in a controlled oxidation process that reaches 2,300°F to destroy PFAS and VOCs and manage emissions.

We provide municipal wastewater treatment facilities with the solution they need to safely remediate biosolids, manage air and odor emissions, reduce their GHG footprint, and generate a beneficial use product from biosolids.

the PFAs remediation cycle.

step 1.

Pyrolysis separates energy compounds and contaminants from biosolids into a pyrogas by heating biosolids in an oxygen deprived environment that avoids burning biosolids. Pyrolysis enables us to remove even the toughest contaminants, such as PFAS and microplastics from our product, and transfer them into the pyrogas.

step 2.

Pyrogas is immediately remediated in an advanced thermal oxidization process that manages nitrogen-based air emissions and provides an endpoint for PFAS compounds and other contaminants that are currently released into the environment.

step 3.

Heat generated from thermal oxidation is used to dry biosolids, prior to pyrolysis, which reduces natural gas usage 68% compared to conventional biosolids dryers.

step 4.

Benchmark air treatment and a specialized building design manage air emissions and odors to ensure our facilities are not a public health concern nor a nuisance to the local community.

climate impact.

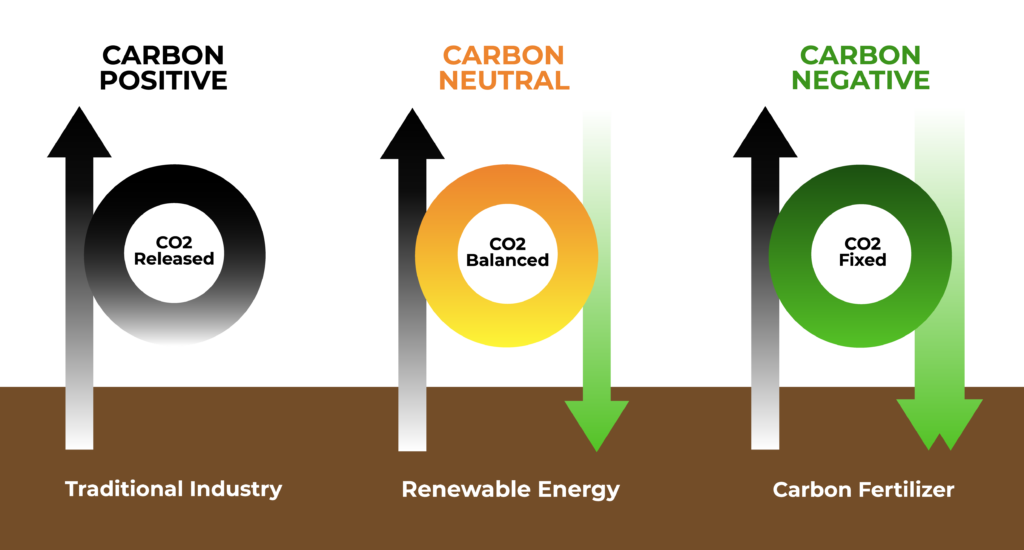

Carbon Fertilizer manufacturing is a carbon-negative climate change tool that is ready for commercial scaling today.

NBS facilities produce a carbon-negative lifecycle greenhouse gas (GHG) footprint as our process displaces CO2e emitting’ fertilizer production and waste disposal processes while sequestering carbon in soil where it is needed.

Relative to our projected facility and transport GHG emissions incurred, our process:

- Avoids GHG emissions from current biosolids disposal solutions (-95%)

- Displaces GHG emissions from chemical fertilizer use (-36%)

- Sequesters GHG emissions from using Carbon Fertilizer (-106%)

Total GHG reductions = -237%

Total Net GHG Reduction = -137%

environmental justice.

Biosolids are commonly disposed of in ways that create disproportionate impacts on economically disadvantaged communities typically in the form of odor and air emissions which can affect human health. Our facilities manage odors and air emissions with finesse to eliminate environmental justice concerns.

- Advanced combustion manages nitrogen-based air emissions and PFAS.

- Comprehensive wet scrubbing system manages air emissions and odors.

- Specialized building manages odors from operations.

- We don’t export the burden from one community to the next!