rooted in responsibility and driven by innovation.

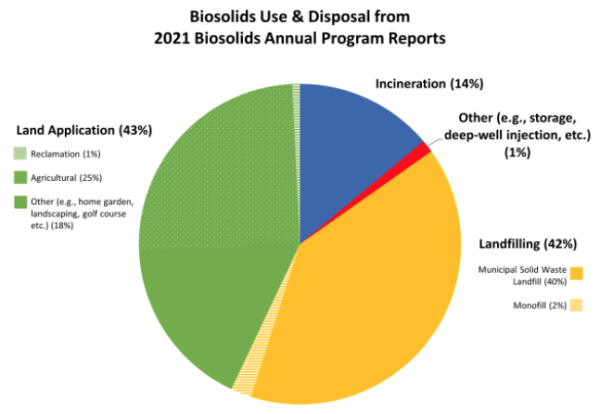

Biosolids are the separated solids from publicly owned wastewater treatment plants (WWTPs). They represent an age-old waste problem that is further complicated by PFAS and other contaminants today. Biosolids are considered a nuisance, non-hazardous waste that is typically disposed of via:

- Land application (43%) is the most popular and lowest cost option that recycles organic matter and nutrients.

- Incineration (14%) is a distant third that is being phased out due to emissions management.

- Landfill (42%) is the most popular option in densely populated like New York State where it accounts for 68% of biosolids disposal.

Carbon Fertilizer is made in the USA from recycled American organic matter, carbon, and nutrients and is based on nature’s recipe for soil health.

biosolids impact the environment.

Biosolids impact the environment, society, and governance (ESG). To put it bluntly, biosolids directly impact human health and environmental justice due to the following reasons:

- PFAS & Contaminants

- Pathogens & Vectors

- Air & GHG Emissions

- Nuisance Odors

- Nutrient Pollution

- Habitat Destruction

biosolids generation continues to grow.

Biosolids generation continues to grow with population and connected sewerage systems, but its disposal is more constrained than ever.

- New York recently released new biosolids PFAS legislation for land application and compost.

- Maine and other states have banned land application of biosolids due to PFAS.

- Clean Air Act increased the cost of compliance for incinerators, and many are closing.

- Landfills are reducing acceptance and are increasingly difficult to permit.

where will it go? what's next?

NBS has tailored its solution to what municipalities desire most.

Northeastern Biochar Solutions (NBS) has designed a process that answers the questions regulators and wastewater treatment facilities are asking themselves; “where will it go?” and “what’s next?”. NBS has tailored its solution to what municipalities desire most.

- Remediates PFAS and contaminants.

- Ultra-low Air and Odor Emissions.

- Negative GHG footprint.

- Beneficial-use product.

- Low operating/utility cost.

- Compliant today, and tomorrow…

our

Carbon Fertilzer.

At the same time, agricultural producers desire solutions that rebuild soil, reduce costs, and improve yield. They want solutions that reduce nutrient application, improve soil hydration, reduce erosion and nutrient runoff (loss), increase soil resilience to climate change, and utilize existing equipment. NBS has tailored its product, Carbon Fertilizer, to the needs of ag-producers and the environment.

- Slow-release nutrients on demand, as needed.

- Restores soil organic matter and carbon.

- Improves moisture retention.

- Reduces nutrient runoff/losses and erosion.

- Doesn’t contaminate soil.

- Compatible with existing assets/equipment.

multi-use bio-fertilizer.

Our Carbon Fertilizer is a multi-use bio-fertilizer, a stand-alone solution perfect for gardens, horticulture, and agriculture.

With its versatility, it serves as an excellent base ingredient to mix with other fertilizers, soil amendments, and grow mediums to suit your specific needs. It also acts as a viable soil remediation solution, effectively sequestering and bonding contaminants in the soil. By incorporating phytoremediation strategies, it becomes a powerful ally in enhancing plant tissue growth while simultaneously purifying the soil.

Unlike traditional fertilizers that degrade soil with their salt content, our bio-fertilizer uniquely binds nutrients with organic matter and carbon. This promotes healthier soil as organic matter feeds microbial life and restores vital biological processes, fostering a thriving ecosystem beneath the surface. Our bio-fertilizer’s carbon sequestration capabilities work wonders for the long-term health of the soil. By improving water and nutrient retention in perpetuity, it ensures your soil remains fertile and productive.

Sustainability creates and maintains the conditions under which humans and nature exist in productive harmony, that permit fulfilling the social, economic, and other requirements of present and future generations.

US Environmental Protection Agency