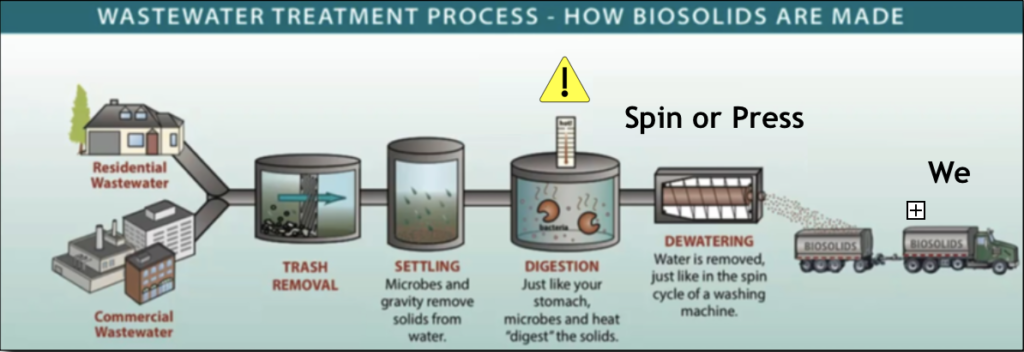

process

biosolids

pyrolysis

Carbon fertilizer manufacturing

- Our pyrolysis kiln reaches material temperatures greater than 1,100⁰F to fully separate PFAS compounds and other VOCs from the solids, into a gas form (i.e., pyrogas).

- Our advanced combustion process remediates the pyrogas generated in pyrolysis and wastewater at 2,300⁰F which breaks down PFAS compounds and other VOCs into:

– Simpler compounds which are addressed, as needed, in a robust air treatment system to meet the strictest State air requirements nationally (i.e., NYS CLCPA).

– Thermal energy that displaces natural gas in pre-drying biosolids.

- Carbon Fertilizer recovered by pyrolysis is essentially foregone air and GHG emissions compared to incineration.

- Most of the carbon recovered by pyrolysis is fixed, or petrified, in a form that is stable for centuries to permanently improve soil hydrology while sequestering carbon in perpetuity.

- Its application as a fertilizer restores soil while replacing chemical fertilizers that degrade soil and have a heavy GHG footprint.

Anaerobic digestion (AE)

Anaerobic Digestion (AD) is a common approach for reducing biosolids generated at WWTPs. AD systems have been deployed since the early 1900s and are currently resurging in popularity today due to governmental incentives. AD is a biological process that breaks down VOCs into carbon dioxide and methane in an oxygen starved environment much like a mammal’s stomach. Up to half of the biosolids volume is converted into gases while the balance requires dewatering and disposal just like undigested biosolids. The primary goals of AD are to (1) reduce the volume of biosolids requiring disposal and (2) generate biogas that can be cleaned up and fed into the natural gas grid (i.e., RNG – renewable natural gas) for RINs. AD concentrates solids and reduces VOCs which means there are relatively more solids to process and less energy to process them with when used as feedstock in a pyrolysis or gasification process. Biosolids can typically reach 25% or higher solids content with AD to reduce transport and drying requirements. However, the energy balance of the pyrolysis/gasification process suffers, and additional natural gas, or the biogas generated from AD, is required to dry and process anaerobically digested biosolids. We recommend utilities seeking to employ our technology to avoid the headaches, expense, and operational complexity AD systems add. However, in the event a utility already has an AD system installed there are several integration options available.

- Bring in additional biomass materials such as wood or food waste.

- Increase solids content of dewatered digestate.

- Blend with biosolids from other WWTPs.

- Utilize AD tanks for biosolids storage.

Contact Us to find out how to integrate our technology.